Safety Glass Identification

Safety Glass

Glass is classified as a 'hazardous building material' in the New Zealand Building Code.

The Acceptable Solution F2/AS1 states that glazing subject to human impact shall comply with NZS 4223:Part3:1999 Code of practice for glazing in buildings - Human impact safety requirements.

Safety glazing materials are those that reduce the likelihood of cutting and piercing injuries resulting from human impact. Bathrooms are an especially high-risk area requiring safety glass, since most glass-related accidents in bathrooms are potentially very serious.

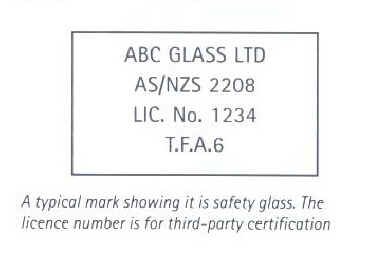

Look for the Label

NZS 4223:Part3:1999 requires all safety glass to be permanently marked, for both building inspectors' and consumers' peace of mind. The marking is usually in a bottom corner so that it is visible when installed, but can be on the edge of thicker toughened glass. Permanently marked does not mean removable labels of any kind. It can be very difficult to identify safety glazing if it is not permanently marked at the time of manufacture. Where there are no markings you cannot tell if it is safetyglass or not, so always assume it is not safety glass.

What the Standard Requires

Clause 303.7 of NZS 4223:Part3:1999 identifies safety glazing materials: 303.7.1 Each panel of safety glazing material shall be legibly and permanently marked. 303.7.3 Each panel shall be marked with the following minimum requirements:(a) The name, registered trademark or code of the manufacturer or supplier;

(b) The type of safety glazing material. This may be in the form of a code, such as T for Toughened glass, or L for Laminated Glass, as indicated by the relevant test Standard (refer AS/NZS 2208);(c) The Standard to which the safety glazing material has been tested, e.g. AS/NZS 2208; (d) If applicable, the classification relating to impact test behaviour, i.e. A for Grade A, B for Grade B.

Validating Safety Glass

Toughened safety glass is normally marked with ceramic ink fused into the glass in the toughening furnace. The manufacturing processes are governed by 'S' Mark or ISO 9000 quality assurance compliance procedures.

Laminated safety glass is permanently etch-marked with chemicals or sandblasting with the label information at the time it is cut from a panel of safety glass.

NZS 4223:Part3:1999 requires safety glass to be tested and to comply with AS/NZS2208, or similar. Third party audited quality assurance markings, such as the 'S' mark, will ensure that these products have been produced by reputable manufacturers.

Do not accept other glass manufacturing standards without checking their validity for the application.

Random Testing

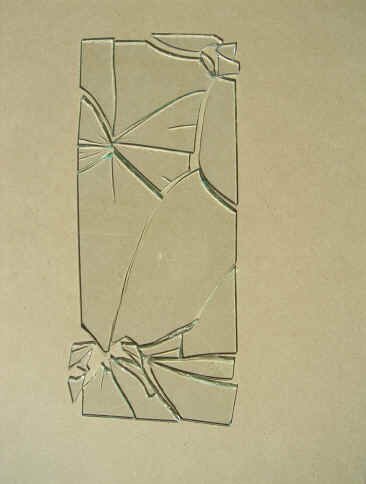

The Glass Association of New Zealand undertakes random testing of unmarked glass sold as safety glass. Even the experts cannot be sure what the result will be before the test is carried out.

The testing includes ensuring that the glass has broken correctly in accordance with AS/NZS 2208.

The photo on the right shows ordinary glass breaking into dangerous shards. There are deaths from injuries with this type of glass, which is why the New Zealand Building Code has strict rules for using safety glazing materials in bathrooms and all other areas where human impact is likely.